Post by : Anis Karim

Food waste is not just a moral issue—it’s environmental, economic and operational. In commercial kitchens, up to one‑fifth of food purchased may go unused or end up as waste. One‑third of all food produced globally is discarded, which contributes to greenhouse‑gas emissions, lost resources and avoidable cost. A zero‑waste kitchen approach reshapes how food is procured, prepared, served and even perceived.

The gains are real: less waste means lower costs, better sourcing, sharper menus and stronger brand reputation. For kitchens operating today, especially in 2025, zero‑waste is becoming not a gimmick, but a standard of good practice.

A zero‑waste kitchen isn’t about perfection—it’s about designing systems so waste is minimised, repurposed or eliminated. The core idea is to treat every ingredient part as having value: peels, stems, trimmings, bones, over‑ripe produce—not “trash”.

Efforts often include:

Mapping what gets discarded at each stage (prep, cooking, service)

Designing the menu and operations around minimal leftover ingredients

Training staff to see potential in every part of an ingredient

Building reuse or composting loops so even unavoidable waste becomes input for something else

Tracking waste volumes and cost savings to embed the system into the business model

This mindset shift—from “discard what we don’t use” to “plan what becomes waste” — is what separates casual recycling efforts from truly systemic zero‑waste kitchens.

Here are some of the key systems professional kitchens are using to transform towards zero‑waste:

Before you reduce waste, you need to know what’s being thrown away. Many kitchens begin by tracking bins, scraps, spoiled items and packaging for a week or two. This audit reveals the major waste points: prep trimmings, expired ingredients, plate waste, packaging, etc. Once mapped, you can design interventions around the biggest streams.

Some kitchens now engineer their menus by asking: what by‑products will this dish create, and can those become new ingredients? For example, vegetable peelings might go into stock; bread crusts become breadcrumbs; fish bones become fish stock. This “closed‑loop” thinking means dishes are designed not only for flavour and cost, but also for minimal waste creation.

Kitchen staff must shift mindset: a carrot top isn’t scrap, it’s potential pesto; a yolk white might become meringue or custard. Staff need training in which parts of ingredients can be repurposed, how to store leftovers safely, how to rotate and freeze correctly, and how to identify when reuse becomes risk. When staff feel empowered—not burdened—the system is more likely to succeed.

A successful zero‑waste kitchen often has dedicated workflows or stations for repurposing. For example: a ‘stock‑station’ where bones, shells and trimmings are diverted; a ‘bread station’ where day‑old loaf becomes croutons or breadcrumbs; a ‘fermentation station’ where peel or stems become relish or pickles. This ensures repurposing isn’t ad‑hoc, but built‑in.

Continuous improvement depends on measurement. Kitchen teams track food cost savings, waste weight, number of repurposed items, staff innovation metrics and sometimes even carbon footprint equivalents. They review what works weekly or monthly—and adjust recipes, prep timing or procurement accordingly.

Zero‑waste kitchens often source more carefully: local and seasonal produce, smaller quantities, just‑in‑time delivery. This reduces spoilage. Purchase packaging‑minimal produce where possible. Good storage practices, FIFO (first‑in, first‑out) rotation and usable life tracking are part of the procurement‑inventory system.

Here are simple tactics chefs share which work fast and don’t need years of overhaul:

Use vegetable stems, leaves and stalks in stocks, sautés, or pickles.

Keep bread ends and stale bread for breadcrumbs, croutons, or bread pudding.

Freeze scraps in labelled bags for later stock or sauce bases.

Set up composting for items that can’t be reused, rather than sending them to landfill.

Use citrus peels, tea leaves and coffee grounds as flavour infusions or cleaning aids.

Review portion sizing and plate waste regularly—adjust based on what customers leave.

Train staff with a “one dish a week from leftover” challenge to build habit and morale.

Establish clear bins or labels: one for stock, one for compost, one for true discard.

Audit packaging and find ways to reduce or reuse containers, wrappers and bags.

Share the savings with staff or create a team scoreboard—waste reduction becomes a culture.

These are not heroic leaps—they are incremental wins. Over time the cumulative effect is significant.

When a kitchen implements zero‑waste systems, the benefits ripple out:

Lower food cost: Less waste means less money thrown away, which boosts profitability.

Brand value: Tune into consumer consciousness—diners increasingly value sustainability and transparency. A restaurant that runs a zero‑waste kitchen can differentiate itself.

Menu creativity: Constraints often spark creativity. Repurposing scraps forces chefs to think differently, which can lead to new signature dishes.

Environmental impact: Reduced food waste means less methane, less landfill, fewer wasted resources and lower carbon emissions.

Staff engagement: When team members are empowered to innovate, they feel ownership and pride. It turns kitchen work from repetitive to inventive.

Operational efficiency: Fewer over‑stocks, less spoilage, clearer workflows and better storage practices improve overall kitchen operation.

While the upside is clear, kitchens face challenges in implementing zero‑waste:

It may feel like extra work initially. Staff used to discarding certain items have to retrain to think reuse. Clear leadership, training and visible wins early on help overcome resistance.

Composting systems, better storage, dedicated repurpose workstations or technology may require upfront cost. However, many kitchens view this as investment with medium‑term payback through waste savings.

Seasonal produce, inconsistent packaging, delivery irregularities and unpredictable spoilage can disrupt waste‑reduction plans. Robust inventory systems and flexibility help mitigate this.

Ensuring that repurposed ingredients remain safe, high quality and useable requires training, documentation and oversight. A carrot top can become pesto—but only if cleaned, stored and used properly.

Tracking waste, analysing data and adjusting is consistent work. Some kitchens lose momentum. The solution: embed the measurement into routines, celebrate wins and keep staff engaged.

Several kitchens around the world are already showing how zero‑waste isn’t just theory—it works:

One kitchen in India reduced food‑service waste by nearly 40 % by training staff, repurposing scraps, sourcing locally and designing menus with waste in mind.

A restaurant in Mexico City operates with no bin in the kitchen: every ingredient part is repurposed or composted. The chefs use peel, fish guts, stems and fermentation to turn what would be waste into flavour.

Hotels using AI‑powered tracking systems (smart scales, cameras) have cut food‑waste in their kitchens by half or more in under a year—highlighting that tech plus process works.

These examples show two things: the mindset shift is real, and technology plus human system change is powerful.

Zero‑waste systems aren’t only for professional kitchens. Home cooks and smaller operations can borrow many of the concepts:

Do a mini‑audit for a week: keep track of what you throw away.

Repurpose scraps: vegetable peelings into stock or soup; stale bread into croutons; citrus peels into oils or cleaners.

Use storage, labeling and freezing to extend ingredient life and avoid spoilage.

Compost whatever you can’t repurpose.

Challenge yourself: one “leftover dish” per week made from items you would have thrown away.

Shop smarter: buy local, in smaller quantities, use seasonal produce, avoid excessive packaging.

Build habit: the system matters more than perfection. Each small win accumulates.

As we look ahead into 2025 and beyond, here are systems and trends gaining traction in the zero‑waste kitchen world:

Digitised waste‑tracking platforms: Smart scales, cameras and AI systems that monitor kitchen waste, alert operators and provide analytics.

Circular economy sourcing: Partnerships between farms, restaurants and composting systems so that food streams flow in loops rather than linear models.

Ingredient innovation: Developing new uses for by‑products (e.g., pulps, skins, stems) and creating menu items built around them.

Regulation and certification: As diners demand sustainability, kitchens will increasingly be held to standards or certifications for waste performance.

Training and certification programmes: Staff across kitchens will receive zero‑waste education, making it a legitimate culinary skill.

Smaller footprint menus and modular operations: Kitchens designing menus that flex daily based on waste data—precise ordering, just‑in‑time produce delivery.

These systems will not only improve kitchens but shift consumer expectations—sustainability, transparency and zero‑waste will move from optional to expected.

Zero‑waste kitchens are no longer a niche aspiration—they are a realistic, practical model for modern food operations. With the right systems—waste audits, menu design, staff training, repurposing workflows and measurement—chefs and kitchens can reduce waste, cut cost, boost brand value and innovate their culinary offering.

The shift is as much cultural as it is operational. It demands a mindset that says: what others see as waste, we see as ingredient. In that mindset lies creativity, cost‑control and sustainability.

Whether you’re leading a professional kitchen or cooking at home, the easy wins and systemic changes outlined above can help you start today. The journey isn’t about perfection—but about progress. Every peel, every crumb, every reuse counts.

Predictheon Wins WHX Xcelerate Innovation Champion 2026

Predictheon won WHX 2026 Xcelerate, earning US$12,000, WHX 2027 space and global exposure for its AI

Omantel Launches Otech to Drive Oman’s Future Tech Vision

Omantel launches Otech to accelerate Oman’s digital transformation, strengthen data sovereignty, exp

Daimler Truck MEA Honors Top Distributors at EliteClass 2025

Daimler Truck MEA hosted EliteClass Awards 2025 in Dubai, honoring top distributors across 19 catego

King Mohammed VI Launches Safran Landing Gear Plant in Morocco

Morocco strengthens its aerospace leadership as King Mohammed VI launches Safran’s €280M landing gea

Qatar Emir Sheikh Tamim Arrives in UAE on Fraternal Visit

Qatar’s Emir Sheikh Tamim bin Hamad Al Thani arrived in Abu Dhabi on Saturday. UAE President Sheikh

Shaidorov Wins Stunning Olympic Gold as Malinin Falters

Kazakhstan’s Mikhail Shaidorov won men’s figure skating gold after US star Ilia Malinin fell twice.

Shakira’s 5-Show El Salvador Residency Boosts Bukele Image

Shakira’s five sold-out concerts in San Salvador highlight El Salvador’s security shift under Bukele

Why Drinking Soaked Chia Seeds Water With Lemon and Honey Before Breakfast Matters

Drinking soaked chia seeds water with lemon and honey before breakfast may support digestion hydrati

Morning Walk vs Evening Walk: Which Helps You Lose More Weight?

Morning or evening walk Learn how both help with weight loss and which walking time suits your body

What Really Happens When You Drink Lemon Turmeric Water Daily

Discover what happens to your body when you drink lemon turmeric water daily including digestion imm

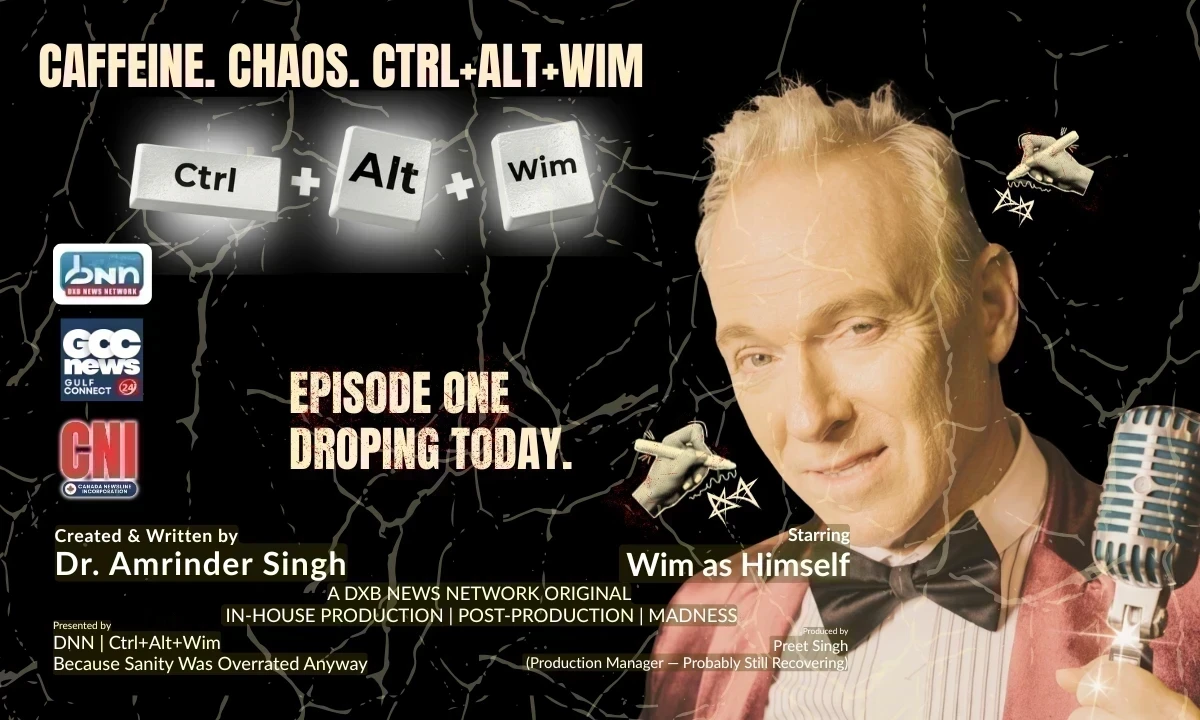

DXB News Network Presents “Ctrl+Alt+Wim”, A Bold New Satirical Series Starring Global Entertainer Wim Hoste

DXB News Network premieres Ctrl+Alt+Wim, a bold new satirical micro‑series starring global entertain

High Heart Rate? 10 Common Causes and 10 Natural Ways to Lower It

Learn why heart rate rises and how to lower it naturally with simple habits healthy food calm routin

10 Simple Natural Remedies That Bring Out Your Skin’s Natural Glow

Discover simple natural remedies for glowing skin Easy daily habits clean care and healthy living ti

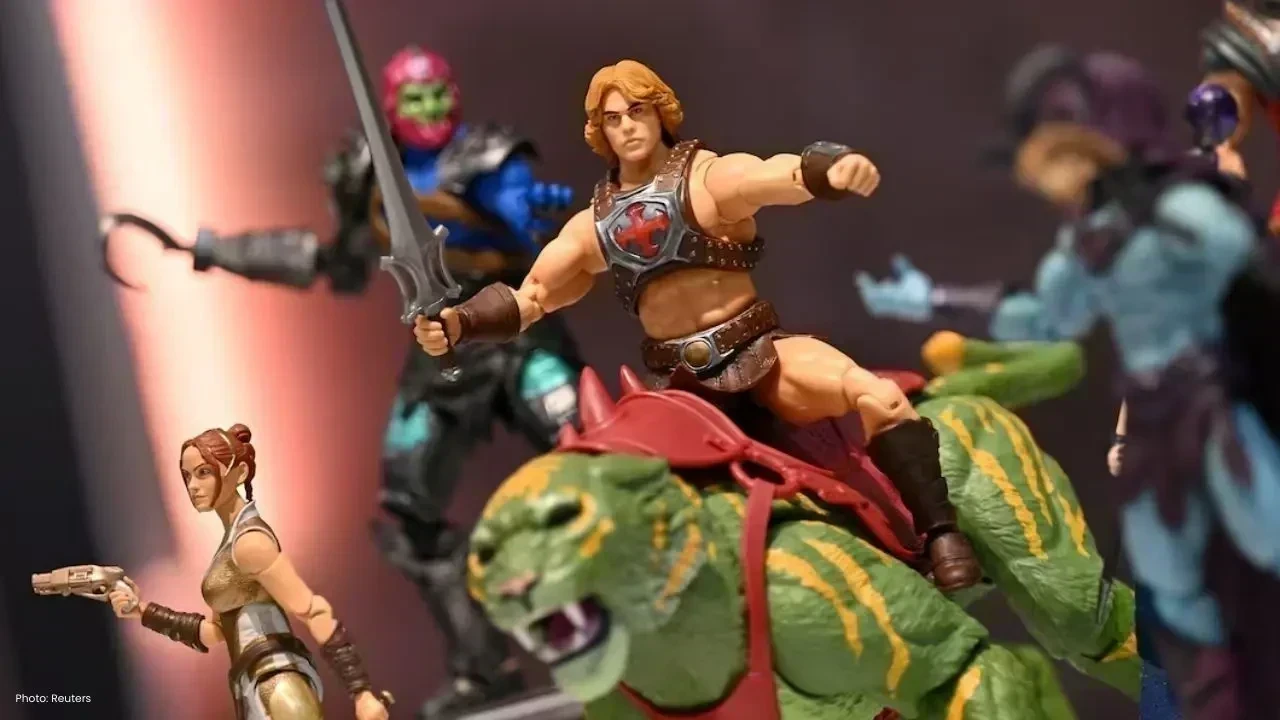

Mattel Revamps Masters of the Universe Action Figures for Upcoming Film

Mattel is set to revive Masters of the Universe action figures in sync with their new movie, ignitin

China Executes 11 Members of Infamous Ming Family Behind Myanmar Scam Operations

China has executed 11 Ming family members, linked to extensive scams and gambling in Myanmar, causin